Phone:

+90 532 477 93 07

Address:

KIRKGOZ INDUSTRIAL SITE, 2869 STREET:16, 2861 St. 07190 Dosemealti/Antalya, Turkey

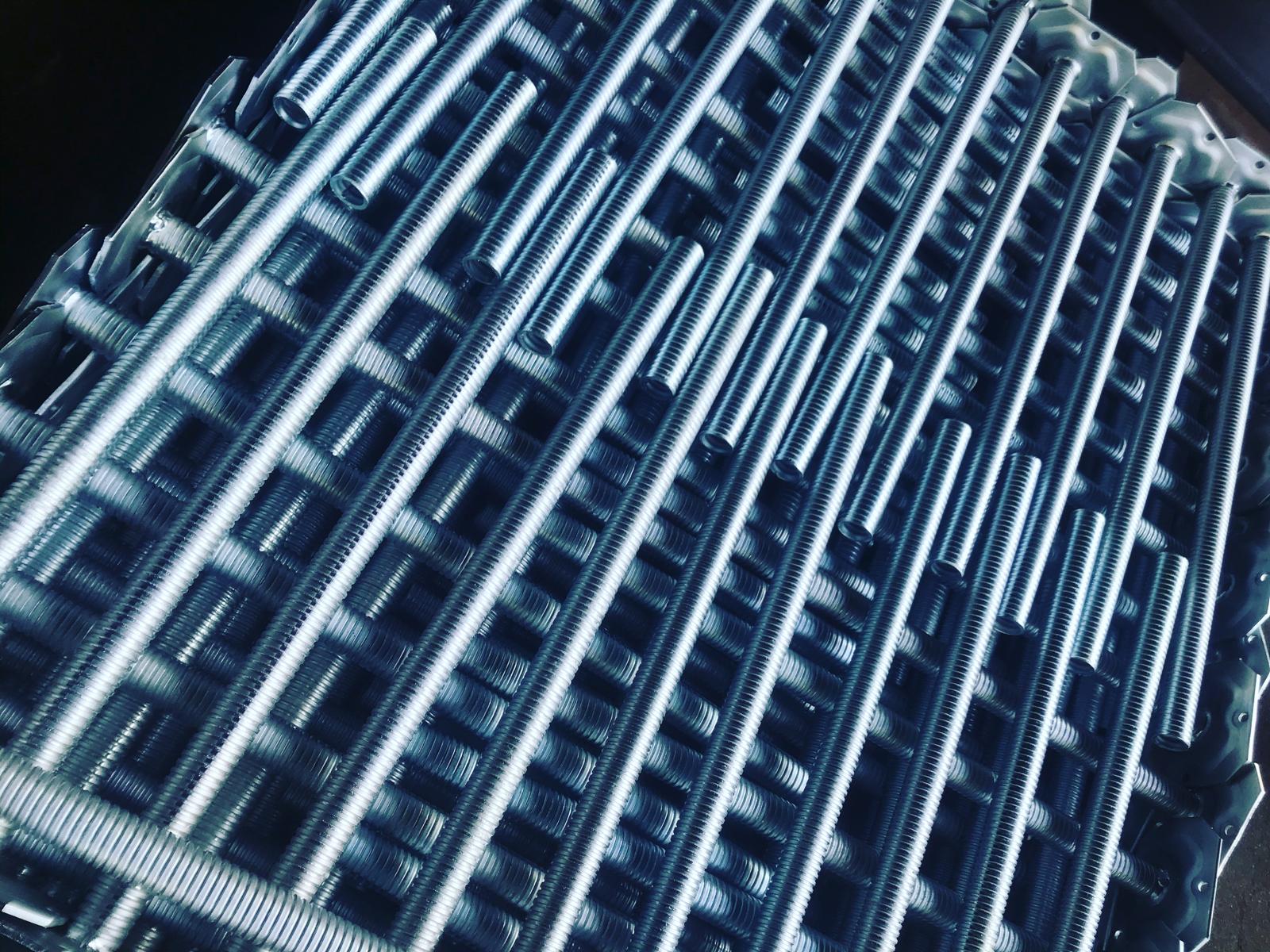

Galvanizing coating is one of the most effective methods for protecting metal surfaces against corrosion. In this process, zinc is coated onto iron and steel products, greatly preventing rust and wear. As a result, products become more durable, long-lasting, and aesthetically pleasing.

Our Galvanizing Coating Pool Capacity

As Lima Metal Çelik, we can easily process products of different sizes thanks to our large pool sizes. Regardless of the scope of your project, we offer reliable and long-lasting solutions with our team’s expertise and technological infrastructure.

You can choose Lima Metal Çelik’s Galvanizing Coating service to protect your products from rust and corrosion, reduce maintenance costs, and extend their lifespan. Don’t hesitate to contact us for detailed information and quote requests!

Discover the Right Galvanizing Solution for Your Products!

Contact Lima Metal Çelik for quality and reliable solutions. Our expert team is here to provide the most suitable service for your projects.

About Galvanizing Coating

Galvanizing coating is the process of coating iron and steel materials with zinc. This makes metals more resistant to corrosion, rust, and wear.

Electro Galvanizing: The process of coating zinc onto metal surfaces using electric current. It provides a thinner and more uniform coating.

Hot-Dip Galvanizing: Metal is immersed in a molten zinc bath. A thick and strong zinc layer is obtained, ideal for heavy loads or harsh environmental conditions.

Typically, a bright or matte gray surface is formed. Over time, the patina that forms on the surface helps to protect the metal against corrosion for a long time.

Electro Galvanizing: 120 cm width, 750 cm length, 160 cm depth

Hot-Dip Galvanizing: 150 cm width, 700 cm length, 350 cm depth

The duration varies depending on the project volume, material size, and requested coating thickness. The process is usually completed within a few days, but this period may be extended for larger and multi-part projects.

No additional maintenance is required under standard conditions. However, additional surface treatments (such as painting) may be requested depending on the usage area of the coated parts.

Pricing is determined based on factors such as the size and quantity of the material to be coated, the coating method (electro or hot-dip), and the requested zinc thickness. You can contact us for a detailed price quote.

Yes. As Lima Metal Çelik, we follow international quality standards in our coating processes and have the necessary certifications.